Best 5 Semiconductor Air Pollution Control Solutions to Cut Emissions by 38%

Semiconductor air pollution control has become a top priority as manufacturers aim to reduce emissions and ensure cleanroom safety . As the semiconductor industry experiences rapid growth, the focus on mitigating air pollution emissions has become increasingly paramount. This shift is driven not only by environmental compliance but also by a growing public concern for health and quality of life, alongside the industry’s commitment to green manufacturing for corporate sustainability

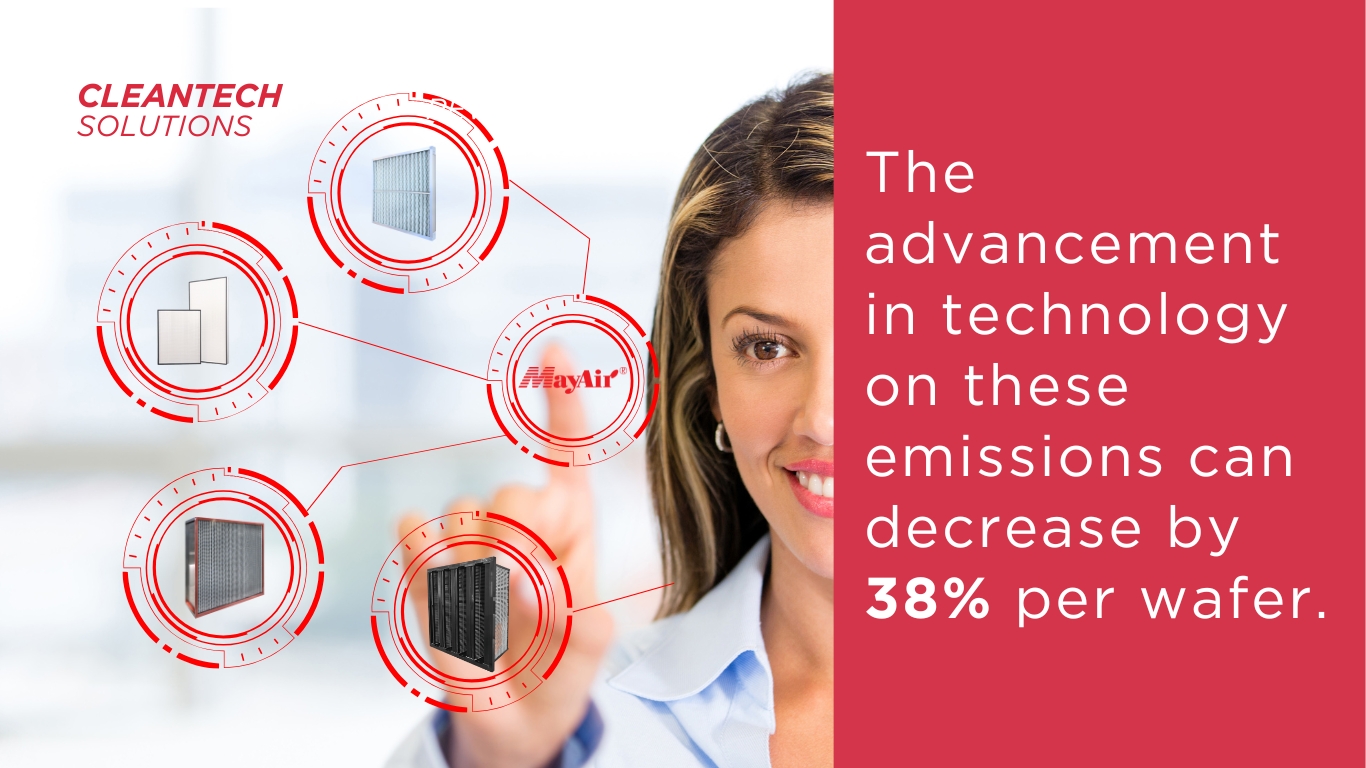

In response to these challenges, maximizing the efficiency of pollution control equipment has become essential. It requires careful consideration of factors such as available resources, space limitations, and advancements in treatment technologies. The goal is to strike a balance between reducing air pollution emissions and operating within these constraints, allowing the semiconductor industry to minimize its environmental footprint while maintaining efficient operations.

Why Semiconductor Air Pollution Control Matters

Semiconductor fabrication involves intensive chemical processing, gas reactions, and heat—all of which contribute to air pollution. Common emissions include:

- Volatile Organic Compounds (VOCs)

- Acidic gases (e.g., HF, HCl)

- Particulate Matter (PM2.5, PM10)

- Ozone and toxic byproducts

Uncontrolled emissions from semiconductor facilities can lead to indoor air contamination, regulatory violations, health risks to workers, and environmental degradation. Cleanroom operations require strict semiconductor air pollution control systems to prevent contamination that could damage wafers and compromise yield.

Complete Semiconductor Air Pollution Control

MayAir delivers a comprehensive suite of solutions to meet the semiconductor industry’s most demanding clean air challenges.

1. ISO-Class Particle Control

Our multi-layer filtration systems capture even the smallest particles at the ISO Class 1 level. ISO 14644-compliant FFUs capture 0.1 µm particles and integrate AMC cartridges to scrub HF, HCl, NH₃, and VOCs below sub-ppb thresholds.

2. Sub-ppb Chemical Filtration

With gas-phase filtration technologies, we remove gaseous contaminants such as hydrogen fluoride, sulfur dioxide, and ammonia to sub-parts-per-billion (ppb) levels, meeting or exceeding industry standards.

3. Custom Ventilation Engineering

Our air-handling units (AHUs) are tailored to semiconductor facility layouts, balancing airflow, temperature, and humidity with compact designs that conserve energy and space.

4. Real-Time Emission Monitoring

Smart monitoring systems track airborne pollutants and filter efficiency continuously. Our IoT-based dashboards alert your team before pollution thresholds are exceeded, ensuring regulatory compliance and proactive maintenance.

5. Carbon Profiling & Waste Optimization

Through carbon profiling tools, we help you map emission hotspots and suggest targeted control strategies to reduce your overall carbon footprint while optimizing operating costs.

Maximizing pollution-control efficiency allows semiconductor fabs to keep pace with soaring chip demand while cutting inorganic-acid emissions per wafer by 38% and meeting ISO Class 1 particle limits with advanced filter technologies.

MayAir’s Role in Green Manufacturing

MayAir provides a complete set of air filtration tools to tackle both particles and chemicals in cleanrooms. Their filters can capture even the tiniest dust particles (meeting ISO Class 1 standards) and reduce chemical contamination to extremely low levels (sub-ppb).

At MayAir, we are proud to lead the way in providing advanced technology solutions for air filtration systems, ensuring that semiconductor manufacturers can meet their production needs while minimizing their environmental footprint.

Our experts work tirelessly to design and implement customized solutions that address the unique challenges faced by semiconductor manufacturers, including maximizing efficiency, minimizing waste, and meeting stringent environmental regulations.

Through our innovative approach and commitment to excellence, MayAir has become a trusted partner for semiconductor manufacturers seeking to reduce their impact on the environment without compromising on productivity.

Together, we can make semiconductor innovation safer, cleaner, and more sustainable, one wafer at a time.

By coupling high-efficiency air-pollution control equipment for semiconductor manufacturing with intelligent filtration and EC-driven airflow, fabs can comply with stricter acid/VOC limits, shrink carbon intensity, and uphold community health without sacrificing yield or productivity. MayAir’s ISO-Class-1 solutions and 24/7 support make it the trusted path to a cleaner, greener wafer future.

Ready to upgrade your semiconductor manufacturing?

Contact us today!